Antibodies are key reagents for functional characterization of the large number of gene products and open reading frames (ORFs) yielded by the various genome projects and the research of the clinical networks. The availability of detection reagents for these gene products is essential for systematic postgenomic research on cell or tissue specific expression patterns, intracellular distribution, complex formation and function of the respective proteins. A huge number of potential protein antigens arose from the human genome analysis alone, with similar needs for animal models, in particular the mouse.

However, animal based antibody generation is limited by the bottleneck of the in-vivo immune response. In animals, it is difficult or sometimes even impossible to raise antibodies against highly conserved (non-immunogenic), toxic or instable protein molecules. In contrast, in vitro methods do not have these limitations. The in vitro antibody selection technique phage display is used in the SMP “Antibody Factory”. It has been validated for more than 10 years by yielding most of the human monoclonal antibodies available today.

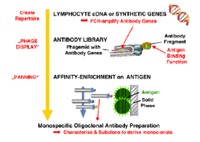

Phage display is based on the connection of the genetic information of antibodies to their gene products displayed on the surface of filamentous bacteriophages. This connection allows the selection of antibody genes by their encoded binding function, by incubating huge gene libraries packaged into a highly complex mixture of antibody phages against immobilised antigens in a process called “panning” (Fig. 1).

Fig 1: Basic principle of in vitro antibody selection by phage display.

Antibody phage display allows to generate antigen binders to molecules which are non-immunogenic in animals. Furthermore, the control of biochemical conditions during the selection process allows to obtain recombinant antibodies to conformation mutants, e.g. after reversible / non-covalent cofactor binding, and to post-translational modifications, e.g. by phosphorylation. Minute variations in antigen structure can also be discriminated, because a fine-tuning of specificity is possible, e.g. by adding a competitor during the in vitro selection. As it is a complete in vitro process, antibody selection by phage display is open to automatisation, for both antigen and antibody generation, as well as for the subsequent validation of the obtained monoclonals.

In addition to the existing mouse monoclonal antibody production capacity – which by the way is far from being sufficient to meet the needs of “postgenomics” analytics – this in vitro antibody selection technique will significantly improve chances and throughput of antibody generation for proteomics, in particular for those antigens which have resisted all efforts to generate antibodies so far.

Structure of the SMP “Antibody Factory”

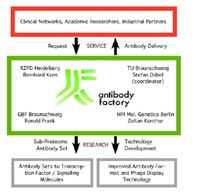

The subprojects of the SMP “Antibody Factory” have been chosen to gain maximum benefit from the existing qualifications, infrastructure and technology for every relevant aspect of the overall structure, i.e. antibody engineering, phage display, robotics for selection and validation, array and database technology. The combination thus offers exhaustive state of the art coverage of all relevant

technologies, both for custom antibody generation and validation and the research elements (Fig. 2).

Fig 2: Structure of the SMP “Antibody Factory

In these four closely interconnected subprojects the SMP “Antibody Factory” will establish a pipeline for the in vitro generation of recombinant antibodies to various antigens. Starting materials will be either the cDNA sequence ID or available antigen. From the sequence ID, either cDNA clones will be selected and expressed, or surface accessible peptides will be generated for panning using phage antibody libraries.

In summary, the SMP “Antibody Factory” aim to lay the foundation for an integrated structure for the throughput generation of recombinant antibodies for the needs of proteome research, in particular to clinical networks and industrial partners.